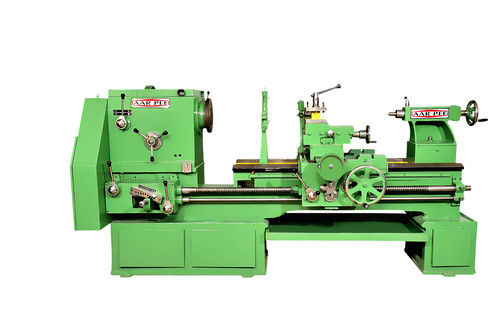

Gear Head Lathe Machine

Product Details:

- Product Type Horizontal

- Material Cast Iron

- Cutting Speed 40-1000 RPM RPM

- Graphic Format Supported DWG

- CNC Or Not Normal

- Automatic Grade Automatic

- Control System Human Machine Interface

- Click to View more

Gear Head Lathe Machine Price And Quantity

- 1 Unit

- 350000.00 INR/Piece

Gear Head Lathe Machine Product Specifications

- 500 TO 700 mm Millimeter (mm)

- DWG

- Automatic

- Human Machine Interface

- Horizontal

- Normal

- 40-1000 RPM RPM

- High Performance, Simple Control, High Efficiency

- 220-440 Volt (v)

- Green

- Cast Iron

- 2000 kg Kilograms (kg)

Gear Head Lathe Machine Trade Information

- Telegraphic Transfer (T/T), Cheque

- 4 Unit Per Month

- 30 Days

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, South America, Asia, Central America

- All India

- As per IS 1878

Product Description

With rich industry experience and knowledge, we are engaged in offering a wide range of All Geared Lathe Machine which has a streamlined modern outlook and contain all the characteristics normally expected in superior quality machines, where precision is necessitated along with stock removal. The offered machine is having the shafts are of special quality steel and are having ground finish. All Geared Lathe Machine is utilized for grinding, shearing and shaping metal pieces. Furthermore, we offer this machine in various specifications at industry leading rates.

Specification :

High Precision, High production Model KRS-25C/100 lathes have a streamlined modern outlook and contain all the characteristics normally expected in superior quality machines, where precision is necessitated along with stock removal.

All the castings are of close-grained, heavy duty alloyed cast iron conforming to different grades of IS : 210 and are amply proportioned to withstand stress without distortion. The Shafts are of special quality steel and are having ground finish. All the bearings, Shafts and gears of the main assemblies run either in oil bath or force-lubricated through proper lubricating pump and network of oil tubing. The Headtock Apron-box and the feed Gear box are of box section. The Shafts are supported on both sides and run on antifriction bearings. The gears are made out of special steel and are hardened. The bores of gears are ground.

Sliding Surface & Screw Cutting Lathes (All Geared head)

Standard Equipment :

Electric Motor with Control Panel, Headstock's and Tailstock's Dead Centre, Thread Dial indicator, Quick Change Gear Box, Square Tool Post, Driving Plate, Set of Spanners & Keys, Instruction Mannual.

Extra Accessories :

Taper Turning Attachment, Copying Attachment, Four Jaw Independent Dog Chuck, True Chuck, Revolving Centre, Electric Coolant Pump with Spout Assembly & fittings, Key Milling and Dividing Attachments, Machine Light etc.

Specification

| Layout | Horizontal |

| Model Name/Number | KRS-25C/100 |

| Automation Grade | Automatic |

| Height Of Centre | 250 mm |

| Material | Cast Iron |

| Voltage | 440V |

| Length Of Bed | 6 to 12 feet |

| Brand | Aar Pee |

| Lathe Machine Type | Horizontal Lathe |

| Brand/Make | AAR PEE |

| Admit Between Centre | 1000 mm |

| Color | APPLE GREEN |

| Max Turning Diameter | 500 mm |

| Spindle Speed Range | 45 to 1000 rpm |

| Width Of Bed | 325mm |

| Swing In Gap | 700 to 900mm |

| Centre Height | 250mm |

| Quill Travel | 200mm |

| Quill Dia | 60 to 80mm |

| Spindle Bore | 53mm |

| Number of Spindle Speeds | 8 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+